| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

GNC CNC MAKİNA TEKNOLOJİLERİ A.Ş.

Yukarı Dudullu Hünkar Sok. No: 4, 34775 Dudullu / Ümraniye / İSTANBUL / TÜRKİYE

|

Contact Info: +90 542 449 4620

Web: https://gncmak.com/

|

Hall: 6

Stand: 635

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Founded in Istanbul in 2010, GNC CNC Makina Teknolojileri; successfully conducting the distribution business in Turkey of high speed and quality machine tools such as VICTOR Taichung, NAKAMURA-TOME, ROMI, VISION WIDE, VONGHLER and LICO. It advances successfully in this route which it has set sail to benefit to the industry and to create added value for its solution partners with its technological equipment and authorized service network. It continues to maximize the level of production efficiency companies and to add more power the power of industrial production of Turkey.

Nakamura Tome SC-100X² CNC Lathe Born To Be Fast The SC-100X² stands out with its unique features. Offering advantages such as easy programming and simple setup, the SC-100X² helps manufacturers reduce initial investment costs while increasing efficiency. SAVE TIME WITH THE SC-100X² What sets this machine apart from others is its dual turret and dual chuck design, along with a C+Y axis configuration and the ability for the sub-spindle to move in 2 axes. This enables the Superimpose Machining function, which significantly reduces processing time. With this model, you can also benefit from Nakamura-Tome s exclusive software and hardware features such as NT-Nurse and NT-Navigator, making it easier to overcome the production challenges you face. If you d like, I can also make this sound more like a marketing-oriented brochure text in English so it s more appealing to potential customers.

Nakamura-Tome WY-100V CNC Turning Center High Speed, Maximum Productivity Part of Nakamura-Tome s new V Series, the WY-100V features the unique ChronoCut software technology, dramatically reducing idle time and shortening overall machining cycles by up to 30%. Precision Through Thermal Compensation The enhanced NT Thermo Navigator system uses real-time temperature data to automatically compensate for thermal deformation, while the newly designed machine structure minimizes heat-related errors for superior accuracy. Dual Turrets, Dual Spindles, Dual Y-Axes Equipped with two turrets, two opposing spindles, and standard Y-axes on both turrets, the WY-100V enables simultaneous left/right and upper/lower machining, significantly reducing cycle times and improving process efficiency. Efficient and Eco-Friendly Design A grease-lubricated system on all linear axes reduces lubricant consumption and maintenance frequency, increasing machine uptime and supporting environmentally friendly operations.

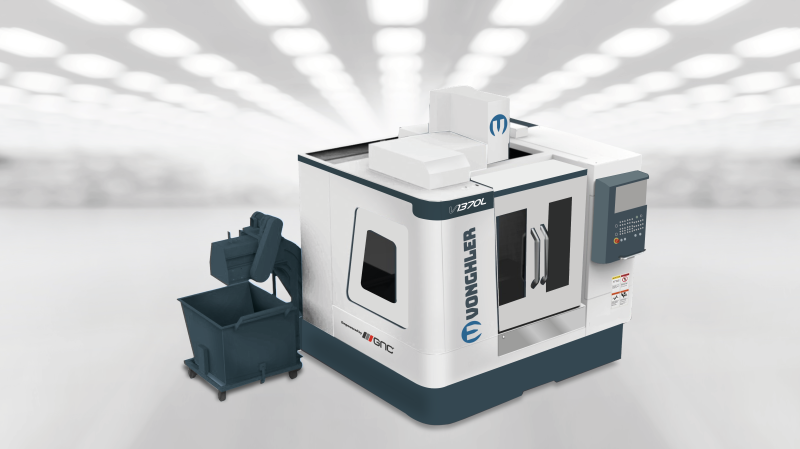

Vonghler V1160L Vertical Machining Center The Vonghler V1160L is a high-performance, reliable vertical machining center. Designed for industrial applications, it delivers exceptional precision and efficiency. Additional Features Mitsubishi M80A control unit 15 display Wireless handwheel Vonghler A GNC Makina Brand! Vonghler was established by GNC Makina to address the current needs of manufacturers through its engineering expertise and technological know-how. By offering advanced CNC machines with a budget-friendly approach, Vonghler plays a key role in GNC Makina s vision of supporting the growth of the Turkish manufacturing industry under the assurance of GNC Makina. Behind Vonghler stands a strong, proven team with a track record of excellence in product quality and customer satisfaction. What Are the Advantages of Mineral Casting Technology? Vonghler machines are manufactured using mineral casting technology with high-quality mineral composite binding materials. These materials provide superior self-compacting performance and achieve vibration absorption capabilities that are 10 times greater than steel or cast iron, significantly reducing external vibrations. In addition, excellent thermal stability ensures that machine accuracy is minimally affected by temperature changes. The use of high-precision molds in mineral casting achieves a casting accuracy of 0.1 mm/m, reducing machining costs and shortening casting delivery times. Vonghler machines also offer strong corrosion resistance and outstanding damping performance, resulting in long-lasting and durable machining solutions. If you want, I can now also adapt this into a short, catchy brochure-style text similar to your SC-100X² and WY-100V examples so it s ready for marketing use.

Perfect Precision, Maximum Efficiency The ONA AD35 is a compact yet powerful EDM machine designed to meet the demands of high-precision manufacturing. With advanced automation options and energy efficiency, it optimizes your production processes while reducing costs through superior surface quality and extended tool life. Wide Machining Capacity: Ideal table dimensions and machining volume for medium-sized parts. Superior Accuracy: Micron-level machining capability to meet the most demanding surface requirements. Energy Efficiency: Intelligent power management ensures low energy consumption. User-Friendly Operation: Easy-to-use control panel and flexible programming features. Automation Ready: Built-in infrastructure for robotic loading and integration into production cells. Create a difference in production with the ONA AD35. Offered with the assurance of GNC Makina, this technology takes you one step closer to the production standards of the future.

5-Axis Power, Fast Delivery, Maximum Efficiency The Victor Taichung FX400 stands out as a high-performance 5-axis machining center that delivers both speed and precision in production. With the advantage of immediate delivery from stock and fast installation, it saves your business valuable time while meeting the toughest machining demands with its robust structure and advanced technology. 5-Axis Simultaneous Machining: Perfect processing of complex parts in a single setup. High Speed & Stability: 12,000 rpm direct-drive spindle for superior surface quality and thermal stability. Powerful Torque: 1260 Nm A-axis torque ensures complete control over demanding contours. Fast Tool Change: 2.4-second tool change for maximum cycle time efficiency. Durable Design: High-rigidity column structure guarantees stability even in heavy cutting. Experience speed, precision, and reliability together with the Victor Taichung FX400.

High Precision, Powerful Performance, Maximum Durability Victor Taichung s F series horizontal CNC lathes are specially designed for heavy-duty machining applications. Among the standout models of this series, the F26/60 offers exceptional rigidity, powerful motor options, and advanced control systems, ensuring reliability and precision even under the toughest production conditions. Designed for Heavy-Duty Machining: Robust structure built to withstand high cutting forces. Powerful Motor Options: Combination of high torque and speed to meet diverse machining needs. Superior Precision: Consistent and reliable results even in demanding tolerances. Advanced Control Systems: Smarter, faster, and more user-friendly production management. Long-Lasting Structure: Maximum durability for long-term operational security. With the Victor Taichung F26/60, experience power, precision, and durability in heavy-duty machining. Take your production to the future with the assurance of GNC Makina.

Robust Structure, High Torque, Maximum Machining Capacity The Victor Taichung Vturn 45 CNC Lathe is a powerful gearbox-driven turning center specially designed for machining large diameters and long workpieces. With its solid body construction, high-torque spindle motor, and durable box-way system, it delivers maximum stability and precision even in the toughest heavy-duty cutting conditions. True 45° One-Piece Body: Optimized design for high rigidity and long-lasting durability. Extended Machining Capacity: Handles workpiece lengths up to 4,250 mm for ultimate flexibility. A2-11 Spindle Standard: Reliable connection and superior performance. Box-Way System: 55 HRC hardened box ways ensure exceptional durability under heavy loads. Two-Speed Gearbox: High torque transmission for full control in demanding operations. Powerful Spindle Motor: 37 kW a30/6000i motor provides high torque and continuous power. With the Victor Taichung Vturn 45, experience the perfect combination of power, precision, and durability in heavy-duty turning. Take your production capability to the next level with the assurance of GNC Makina.

No represented companies found.

The company has no registered brand information.

TR

TR