| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

İNGENİUM MAKİNE LİMİTED ŞİRKETİ

Köprübaşı Mah. 4036. Sok. No: 9/A Serdivan / / SAKARYA / TÜRKİYE

|

Contact Info: +905555882120

|

Hall: 6

Stand: 618

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Ingenium Makine Limited Sirketi, located in Sakarya, supplies wire EDM machines as well as high-precision tool presetting and measuring machines. We aim to provide simple yet effective engineering solutions tailored to enhance your production processes.

MW Series Machines Designed for High-Precision Mold Machining MW series machines are specifically designed to perform complex machining tasks, such as producing high-precision, zero-clearance molds. Structural Features: The machines can achieve Ra 0.4 surface roughness and ±3.0 µm machining accuracy. Standard hardware includes flat-type linear motors with full feedback and optical scales with 0.1 µm resolution. The machine base features a T-shaped wide foundation, where the shorter Y-axis is mounted on the X-axis. This structure prevents bending at the ends during table movement. The work tank has a front-opening door, equipped with an electronic lock to prevent accidental opening. Our in-house developed CNC system supports a multi-language interface and is fully compatible with Sodick control programs. Equipped with a fine water spray system (Ø 1 mm) for stable and high-speed automatic wire threading. For maximum reliability, the wire is cut using localized electric heating, then simultaneously tensioned to ensure the tip is annealed, sharpened, and reinforced.

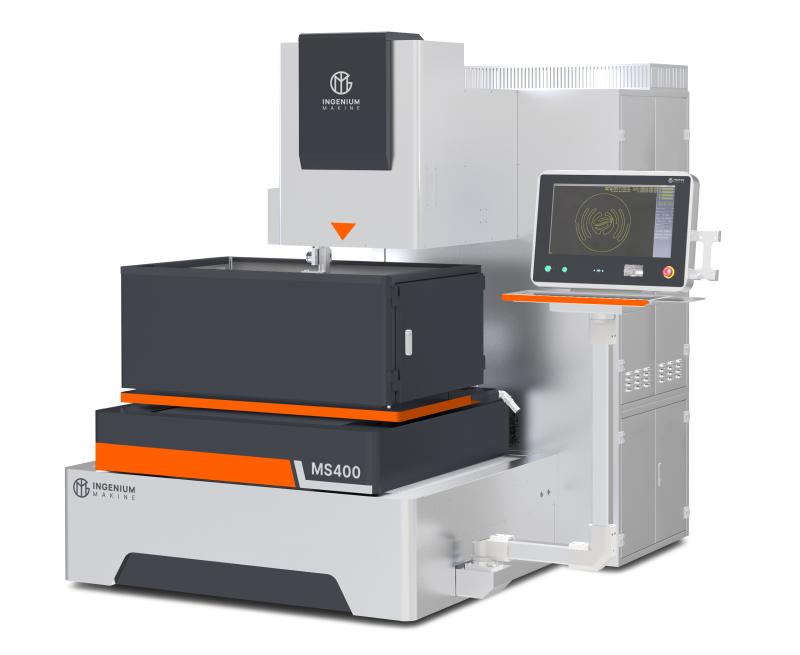

M Series Wire EDM Machines Machining Accuracy: ±6 µm Surface Roughness: Ra 0.8 Key Features: The M Series wire EDM machines use a jet-type design with multi-wire capability, offering a simpler structure and lower operating cost compared to die-sinking EDM machines. Equipped with ME12 multi-pass generators, capable of both rough and fine cutting operations (up to Ra 0.8 surface finish). ME12 generators offer high quality, innovative design, and ergonomic usability. Compatible with various CNC systems: HF, X8, and AutoCut. With M Series machines, you are guaranteed: ? High quality, ? Extended warranty, ? Premium service support, ? Fast delivery, and ? Availability of spare parts for modernization.

CNC320W - Wire EDM Machine The MW series machines are equipped with high precision and advanced hardware, making them suitable for high-accuracy machining of angled workpieces.

MDS143-3 - Die Sinking EDM Machine The MDS Series 1 machines are affordable, reliable, and easy-to-use die sinking EDM machines. In this series, the CNC system controls a single Z-axis. The X and Y axes are equipped with optical scales offering 5-micron precision. The Z-axis is driven by an AC servo motor with feedback from a 1 µm precision encoder. This allows for high-speed Z-axis movement, providing up to 25% higher machining speed when working with graphite and 15% higher speed when working with copper. 15-inch monitor. Current generator with automatic darkening protection function. The spindle drive uses a high-precision, wear-resistant SHVP screw. Applications: Drilling in hard-to-machine materials. Machining shaped surfaces, especially after pre-processing with CNC milling machines in mold production. Manufacturing meshes and grids.

MDS143-1 - Die Sinking EDM Machine The MDS Series 1 machines are affordable, reliable, and easy-to-use die sinking EDM machines. In this series, the CNC system controls a single Z-axis. The X and Y axes are equipped with optical scales offering 5-micron precision. The Z-axis is driven by an AC servo motor with feedback from a 1 µm precision encoder. This allows for high-speed Z-axis movement, providing up to 25% higher machining speed when working with graphite and 15% higher speed when working with copper. 15-inch monitor. Current generator with automatic darkening protection function. The spindle drive uses a high-precision, wear-resistant SHVP screw. Applications: Drilling in hard-to-machine materials. Machining shaped surfaces, especially after pre-processing with CNC milling machines in mold production. Manufacturing meshes and grids.

MD343-1 - Drill EDM Machine Drilling deep holes with diameters ranging from 0.3 mm to 3 mm in metals of any hardness and in hard metal products, while preserving the mechanical properties of the material. Drilling holes, machining complex-shaped blind, stepped, and angled grooves. Manufacturing of molds, meshes, and grids. Drilling control holes in nuts.

No represented companies found.

The company has no registered brand information.

TR

TR