| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SES 3000 CNC TAKIM TEZG. BİLG. SİSTEMLERİ LTD. ŞTİ.

İsmet Paşa Mahallesi Abdi İpekçi Caddesi No: 115-117 / Bayrampaşa / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 674 2508

|

Hall: 5

Stand: 522

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

SES3000 CNC Machine Tools and Computer Systems (CAD/CAM) Ltd. Şti., with the responsibility of its name, has undertaken to provide Sales, Training and Service services to you, our valued industrialists, since its establishment in 1994. Our goal; Our aim is to increase the competitiveness of Turkish industrialists and especially SMEs with the technologies we provide and to ensure higher quality and more efficient production. With this thought, our company has offered the right products to our customers at the right time and has become the SOLUTION PARTNER of our customers by providing training, service and support services with maximum speed. SES3000 Company; MasterCAM Türkiye Distributor YCM SUPERMAX CNC Türkiye Distributor JOEMARS EDM Türkiye Distributor COORD3 CMM is Türkiye Distributor. Our company Ses3000 CNC has received the best-selling company award in Europe for YCM products since 1996. Ses3000 CNC also has the 3rd best-selling company award in the world, after China and America.

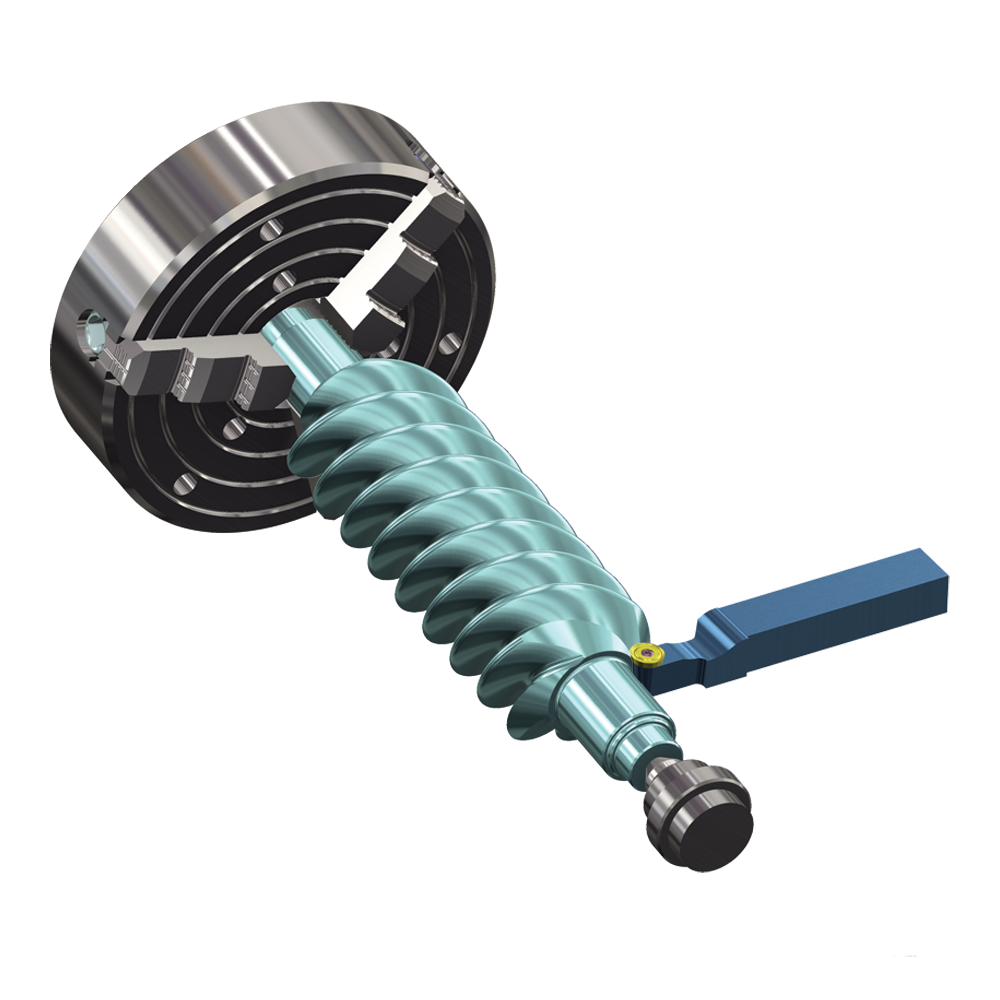

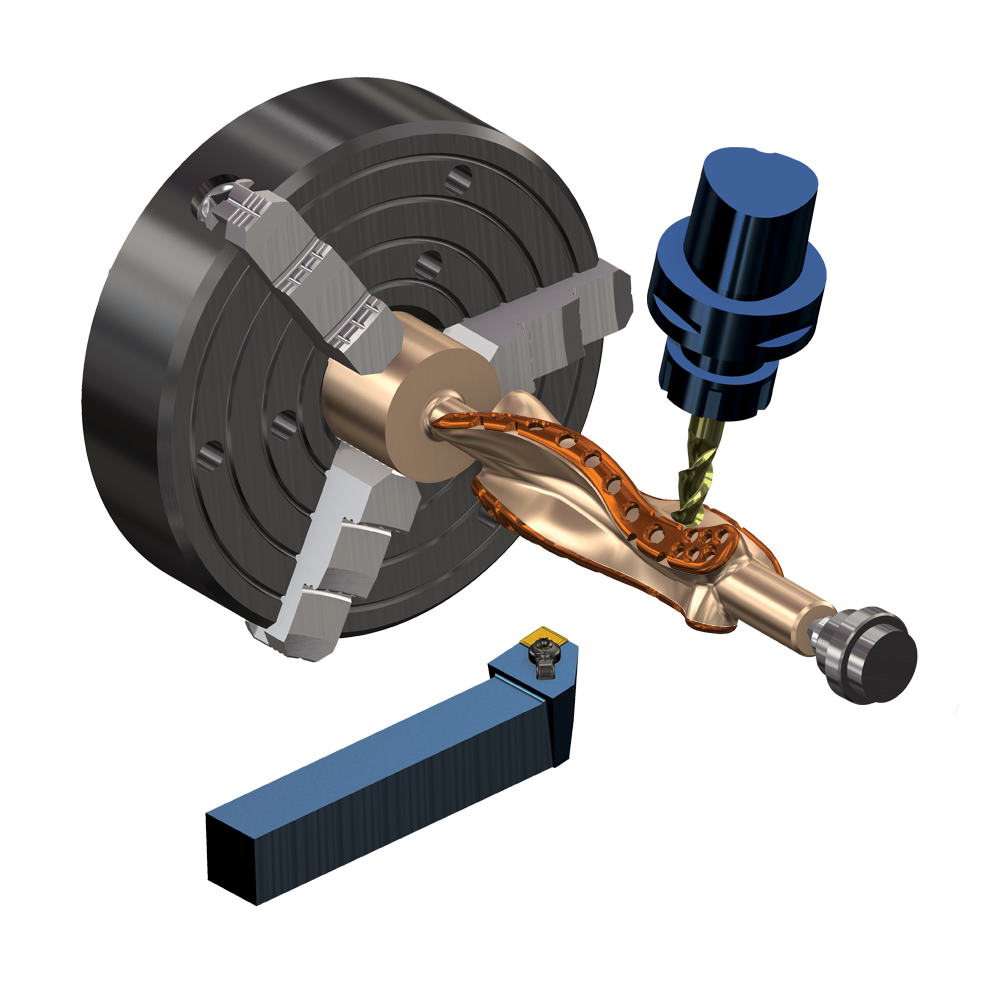

Our turning solutions give you a variety of tools to break down your parts and get the most out of them. Mastercam Lathe provides easy roughing, grooving, threading, parting, drilling and shearing routines to increase productivity.

- MACHINING DIMENSIONS: X1020 mm, Y600 mm, Z600 mm - TABLE LOAD: 700 Kg. - IDLE SPEED: X/Y: 48.000 mm/min. Z: 32,000 mm/min. - CUTTING SPEED: 20000 mm/min. - 3-AXIS DIRECTLY CONNECTED SERVO MOTOR - 24 ATC SLEEVE TYPE, FAST MAGAZINE, PROTECTIVE SENSOR - BBT40 12,000 RPM. /IDD ISOLATED DIRECT DRIVE) - (Option: BBT40 15,000 RPM / IDD ISOLATED DIRECT DRIVE) - Continuous cooling system of the spindle with air conditioning + oil (Spindle Cooling System) - AIR CURTAIN (Prevents dust and water vapor from escaping) - Tool tip cooling feature with AIR - FANUC ALFA α iIT8, 18.5kW (25HP) spindle motor / 120 Nm TORQUE - LARGE STRUCTURED, RIGID AND DESIGNED FOR FAST MATERIAL REMOVAL - MEEHANITE CASTING BODY - X/Y/Z AXES ROLLER SLIDE WAYS -FANUC 200FB+ ADVANCED CONTROL SYSTEM

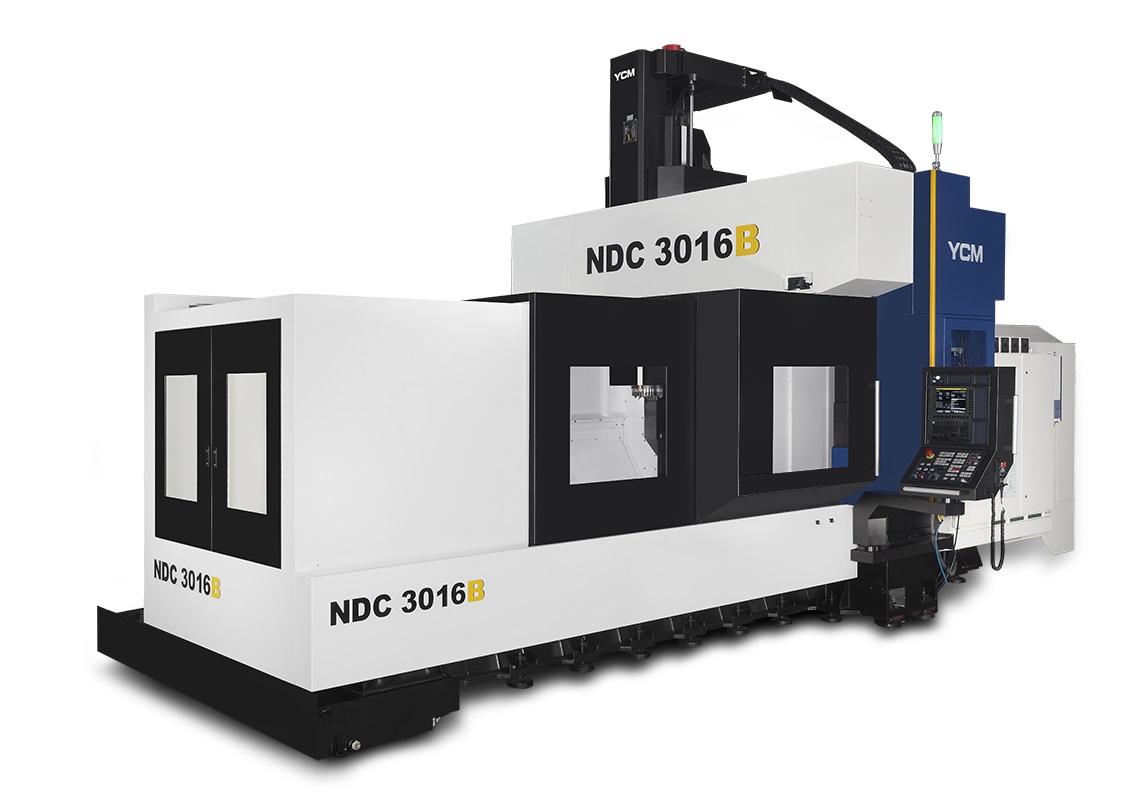

- MACHINING DIMENSIONS: X3200 mm, Y1600 mm, Z762 mm - TABLE DIMENSIONS: 3000 x 1500 mm - TABLE LOAD: 10.000 Kg. - IDLE SPEED: X/Y: 20000 mm/min. Z: 15000 mm/min. - CUTTING SPEED: 10000 mm/min. - 3-AXIS DIRECTLY CONNECTED SERVO MOTOR - 32 ATC ARM TYPE, FAST MAGAZINE, PROTECTIVE SENSOR - BBT50 - 26 kW - 6,000 RPM. / with gearbox) 675Nm Torque - (Option: 45 kW BBT50 10,000 RPM / 475Nm Torque IDD ISOLATED DIRECT DRIVE) - (Option: 30 kW HSK-A100 15.000 RPM / 342Nm Torque IDD ISOLATED DIRECT DRIVE) - Spindle air conditioning + continuous cooling system with oil (Spindle Cooling System) - AIR CURTAIN (Prevents dust and water vapor from escaping) - Tool tip cooling feature with AIR - LARGE STRUCTURED, RIGID AND DESIGNED FOR FAST MATERIAL REMOVAL - MEEHANITE CASTING BODY - COLUMN (BRIDGE AND FEET) ONE PIECE CASTING - X/Y AXES ROLLER SLIDE WAYS - 2 PIECES RECESSED TYPE BOX SLIDE ON Z AXIS - Hydraulic counterweight balancer - FANUC 200FB+ ADVANCED CONTROL SYSTEM

- Axis movements: TC16LB: X150 mm, Z600 mm - Maximum Turning Diameter: Ø 260 mm - Maximum Turning Length: 600 mm - Idle axis speeds: X24 m/min., Z30 m/min. - FANUC TXP-100FA Control NEW CONTROL SYSTEM

MACHINING DIMENSIONS: X800 mm, Y730 mm, Z800 mm TABLE DIMENSIONS: 500 x 500 mm (DOUBLE TABLE A.P.C.) MAXIMUM WORKING DIMENSIONS: Ø880 mm x 1000 mm (H) Rotary Table Indexing Angle: 1 Degree (Option: 0.001 Degree) Table LOAD: 500 Kg. IDLE SPEED: X/Y/Z: 60 m/min. CUTTING SPEED: 40.000 mm/min. 60T (120T) MAGAZINE BBT40 type IDD SPINDLE - 15,000 (20,000) rpm. | 37 kW | 244 Nm Torque Spindle FRONT BEARING diameter: Ø80 mm Air-oil spray lubrication and cooling System (Oil Air Bearing Lubrication System) SPINDLE COOLING SYSTEM SPINDLE AIR CURTAIN (PREVENTS WATER VAPOR AND DUST ESCAPING) MEEHANITE IS LARGE STRUCTURED, RIGID AND DESIGNED FOR FAST MATERIAL REMOVATION CAST BODY LARGE AND RIGID COLUMN DESIGNED FOR HEAVY PASSES X, Y and Z AXES ROLLER TYPE (THK JAPANESE) SLIDE SYSTEM FANUC 200FB+ ADVANCED CONTROL SYSTEM

- MACHINING DIMENSIONS: X620 mm, Y520 mm, Z460 mm - B Axis: 160° (-50°~ +110°) - C Axis (Rotation Axis): 360° - TABLE DIAMETER: ø 650 - TABLE LOAD: 200 Kg. - PART CONNECTING CAPACITY: ø460 - Length 330 - IDLE SPEED: X/Y/Z: 36.000 mm/min. B/C: 25rpm. - CUTTING SPEED: 20000 mm/min. - 3-AXIS DIRECTLY CONNECTED SERVO MOTOR - 24 ATC SLEEVE TYPE, FAST MAGAZINE, PROTECTIVE SENSOR - BBT40 12000 rpm. (IDD) + Oil Air Spindle Technology for 18.5 kW Spindle - Continuous cooling system of the spindle with air conditioning + oil (Spindle Cooling System) - AIR CURTAIN (Prevents dust and water vapor from escaping) - Tool tip cooling feature with AIR - FANUC ALFA α iIT8, 18.5kW (25HP) spindle motor / 120 Nm TORQUE - LARGE STRUCTURED, RIGID AND DESIGNED FOR FAST MATERIAL REMOVAL - MEEHANITE CASTING BODY -FANUC 300FB+ ADVANCED CONTROL SYSTEM

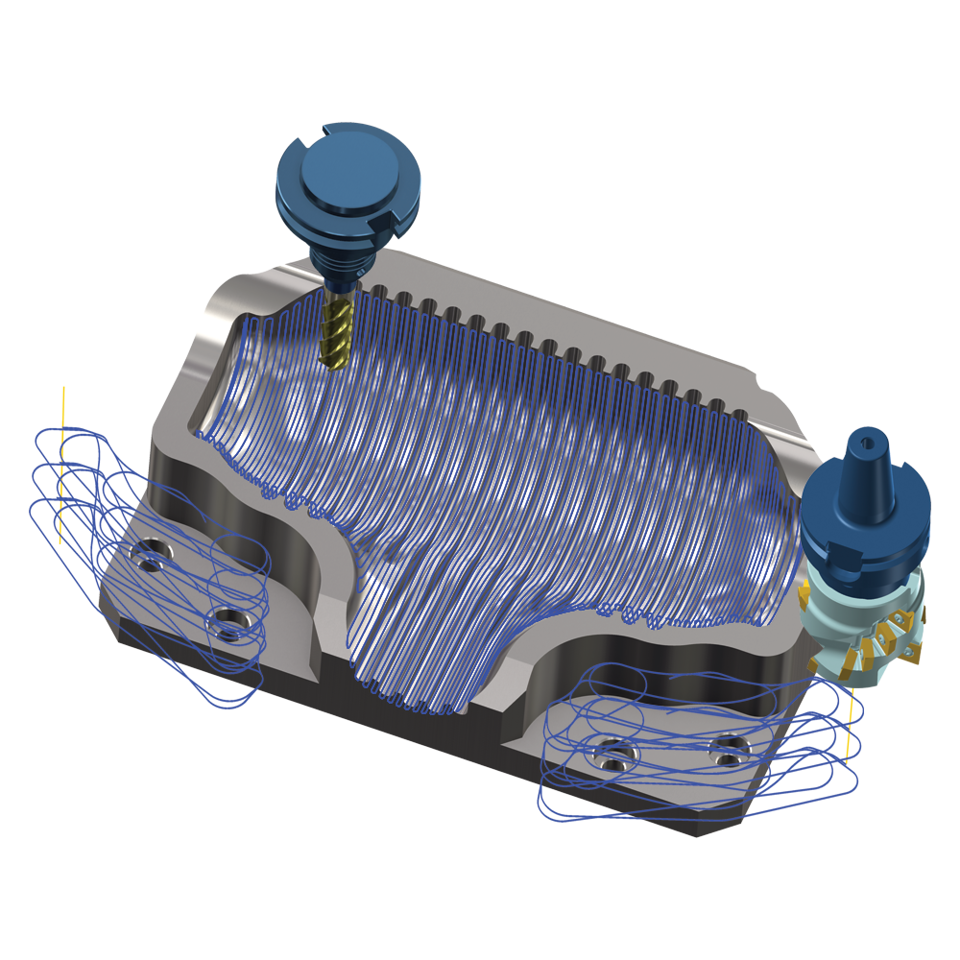

Many of the manufacturing processes we use every day are carried out with the help of Mastercam Milling. This software offers a complete set of machining strategies for your production and much more. Mastercam milling solutions can be customized to the needs of your production processes and easily upgraded to meet your expanding production needs in the future.

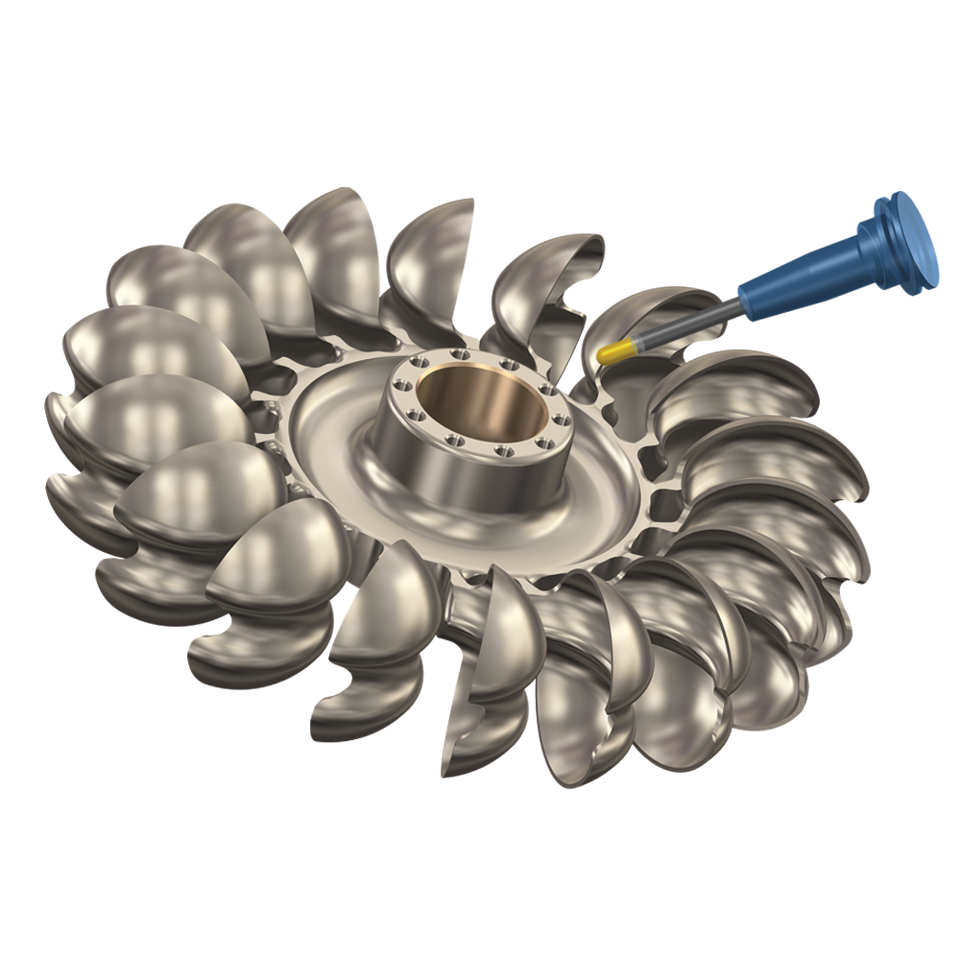

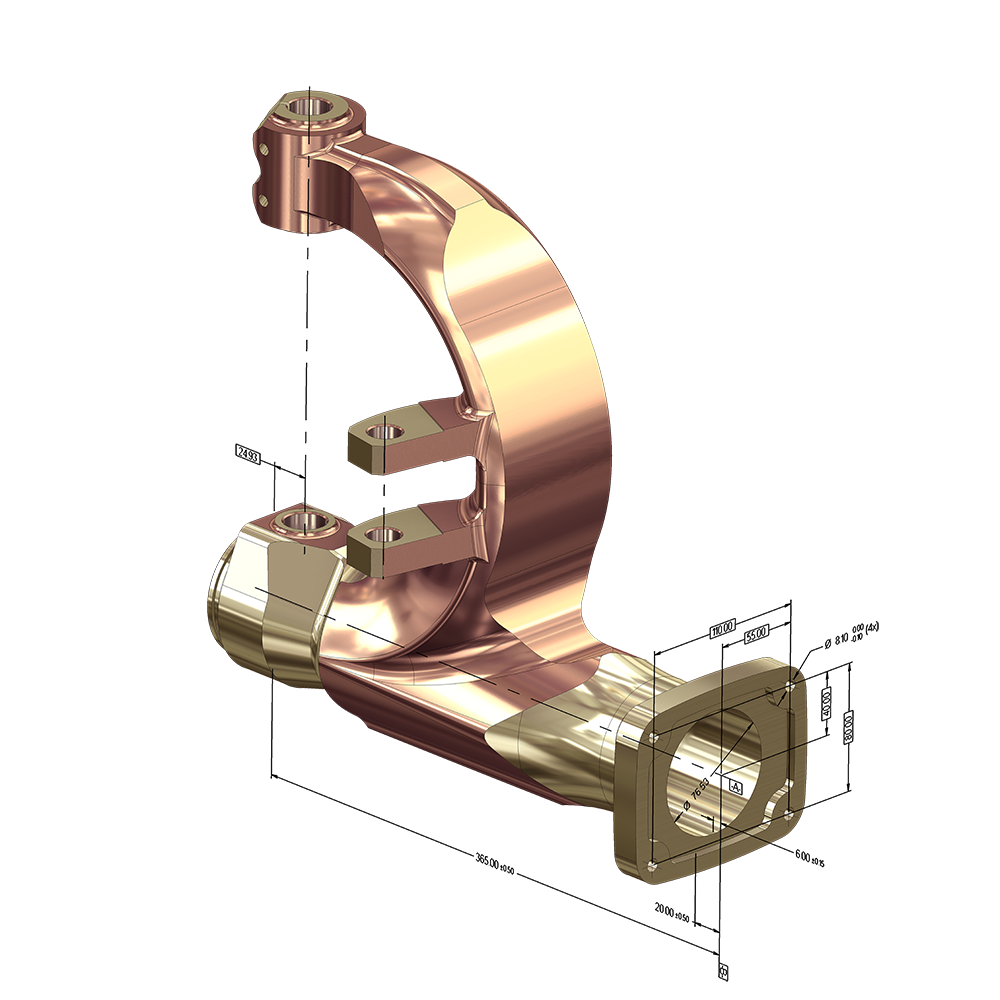

Mastercam Multiaxis offers multi-axis machining strategies that offer a wide variety of command methods, both basic and advanced. Mastercam Multiaxis delivers accurate cuts and fast turnaround on even the toughest jobs with enhanced multi-axis programming for optimum productivity.

Mastercam Mill-Turn simplifies control of high-power, multi-flow machining centers. With Mastercam, your workflow becomes efficient. Select your machine and view Mastercam Turn-Mill part transfers, tool planes, stock definition. And automate the installation. Then extract your toolpaths, quickly sync, simulate your project Verify and submit your code. Making changes to the trading process is quick and easy.

Mastercam Design; Master SOLIDS DESIGN Hybrid modeling and design software; It uses a mixture of wireframe, surface and SOLID modeling techniques simultaneously. Basic solid models are ready in Mastercam Design software, you can take these ready solids from the library, dimension them parametrically and use them.

The company has no registered brand information.

TR

TR