| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

TEKİŞ TEKNİK EROZYON KALIP SAN. VE TİC. A.Ş.

TOSB-TAYSAD 1. Cad. 14. Sok. No. 5 / Çayırova / KOCAELİ / TÜRKİYE

|

Contact Info: +905324578407

|

Hall: 5

Stand: 534B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Founded over 40 years ago, Tekiş has built a strong reputation in the manufacturing sector, initially specializing in high-precision mold sets and exporting them to Europe, particularly Germany. With our roots firmly planted in the mold industry, we have grown into a leading producer of CNC machines, leveraging our deep engineering expertise and commitment to quality. In 2010, we completed our first R&D project under the TÜBİTAK TEYDEB 1507 program, where we designed and manufactured CNC deep hole drilling and horizontal milling machines. Since then, we have been using these machines in our own production processes, offering the highest level of quality by drilling cooling holes with exceptional precision in mold set manufacturing. Our Expertise - CNC Deep Hole Drilling Machines - CNC Horizontal Milling Machines - 6 Axis CNC Deep Hole Drilling and Milling Machines

TEKIS s TDD-1000M model is designed as a CNC Deep Hole Drilling and Milling Machine. This machine has a movement capability of 1000 mm on the W axis, 880 mm on the X axis, 400 mm on the Y axis and 200 mm on the Z axis. It offers hole drilling capacity up to a maximum depth of 1000 mm and in the diameter range of Ø4 - Ø22 mm. It can also perform milling between Ø5 - Ø25 mm and 1-3 step helical gear cutting operations. It reaches a speed of 3000 rpm with ISO40 spindle and has a power of 5.5 kW. The table dimensions are 840 x 550 mm and it has a work loading capacity of up to 4 tons. The total weight of the machine is 2700 kg and the installation area is 2600 x 2200 x 1700 mm.

CNC Horizontal Milling Machine is a machine tool used for machining workpieces with high precision. With its horizontal spindle position, it provides advantages especially in the processing of large and heavy workpieces. CNC horizontal milling machines are widely used in sectors such as automotive, aerospace, moulding and heavy industry.

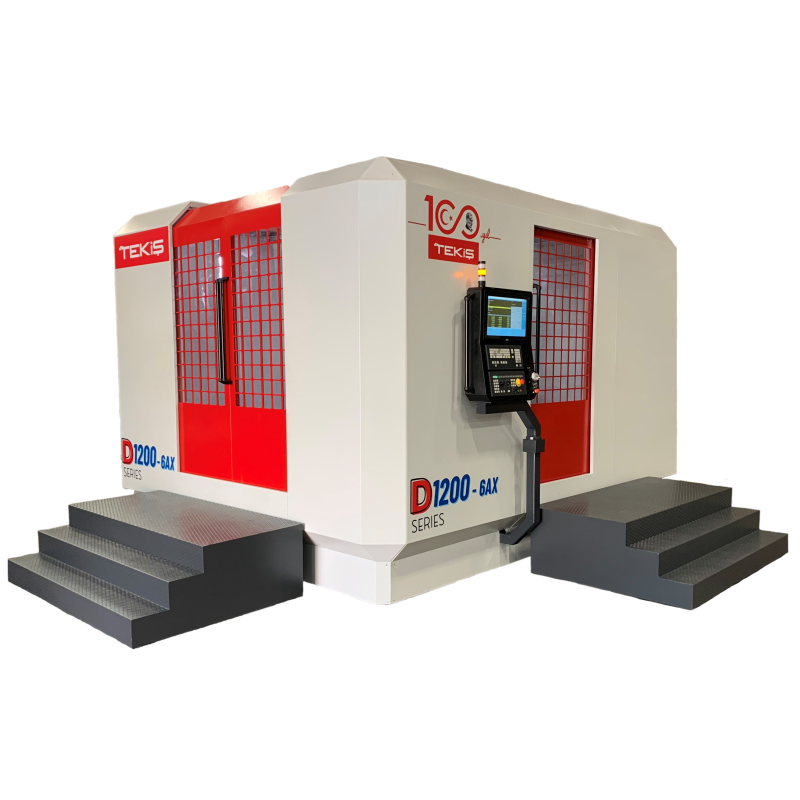

6-axis deep hole drilling and milling machines are advanced technology machines that allow parts with complex geometries to be processed with high precision. These machines are widely used in sectors such as plastic mold, automotive and arms industry. Areas of Use: Plastic Mold Industry: Ideal for high precision hole drilling and milling operations in mold production. Automotive Industry: Used in the processing of engine blocks, chassis components and other critical parts. Weapon Industry: Preferred in the production of barrels and other precision components.

Deep hole drilling is a special processing technique where the ratio of hole depth to diameter is usually greater than 10:1. This method allows long, straight and precise holes to be opened that traditional drilling processes cannot reach. It is frequently used in sectors such as automotive, aviation, hydraulic systems and mold production. Deep hole drilling offers high precision, excellent surface quality and fast production times. This technique is especially critical for high-performance end products. TEKIS TDD-1000 model is a deep hole drilling machine that stands out in this field. This machine is equipped with a PLC control unit and provides high precision and automation. Axis movements are designed as 1300 mm in the W axis, 1200 mm in the X axis, 400 mm in the Y axis and 200 mm in the Z axis. The maximum drilling capacity is 1200 mm and the hole diameter range is Ø4 - Ø22 mm. The spindle is equipped with a Ø25 Veldon holder and can reach a speed of 3000 rpm. The power output is 5.5 kW. The table dimensions are 1100 x 650 mm and it has a workload capacity of up to 8 tons. The total weight of the machine is 2700 kg and the installation area is 2700 x 2100 x 1500 mm. These features make the TDD-1000 an ideal option for various industrial applications. It is used especially for opening high-precision holes in sectors such as automotive, aviation and hydraulic systems. It is also preferred in areas such as mold production and medical device manufacturing. Deep hole drilling is a critical processing method that enables the opening of precise and long holes in modern industry. Advanced machines such as TEKIS TDD-1000 model provide high performance and reliability in this field, increasing the efficiency of production processes.

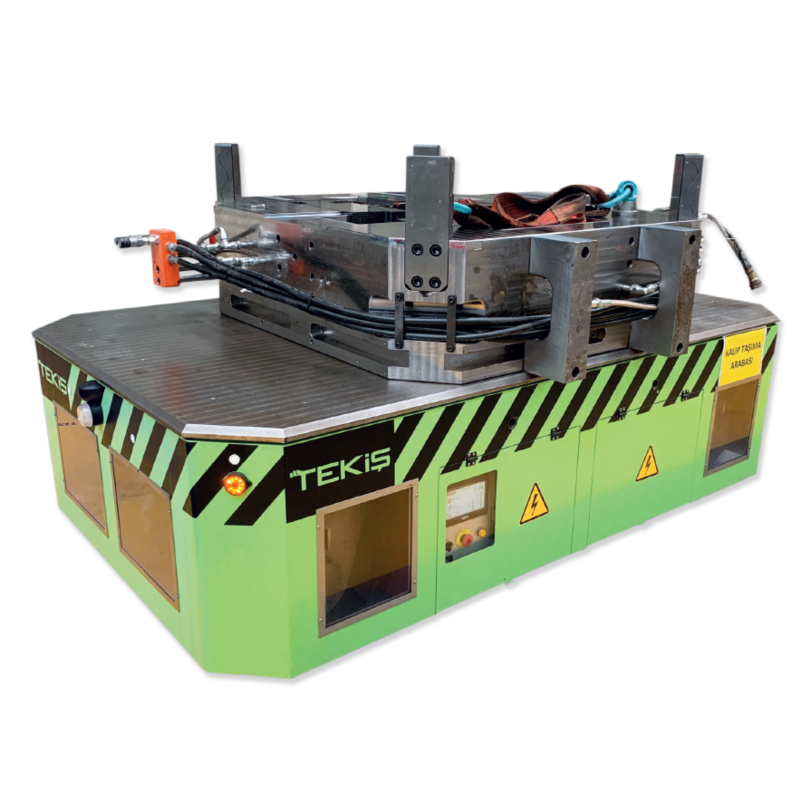

Heavy load handling solutions are critical systems that enable the safe and efficient transport of large and heavy equipment in industrial plants. These solutions contribute to the uninterrupted continuation of production processes, increase occupational safety and increase operational efficiency. In particular, options with different carrying capacities such as 5 tonnes, 10 tonnes, 20 tonnes and 30 tonnes offer flexibility to suit the needs of businesses. Features - 5t, 10t, 20t, 30t Transport Capacity - 360 Manoeuvre - Remote Control - Emergency Stop Button - 48V DC 210 Ah Battery - Distance Adjustable Laser Sensor - Audible and Led Lighted Crash Risk Warning

No represented companies found.

The company has no registered brand information.

TR

TR